|

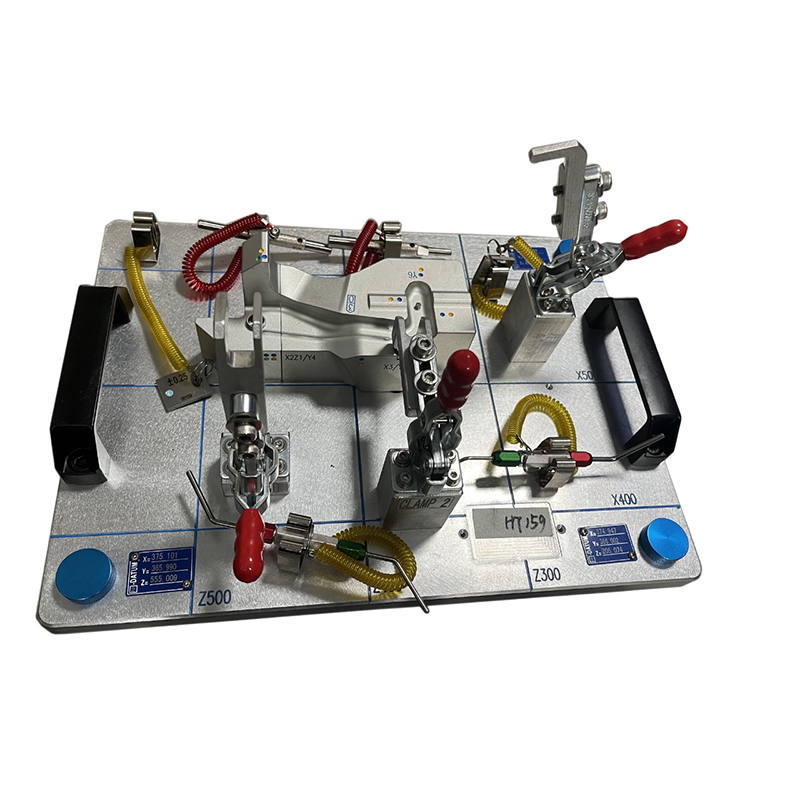

HTCK-003 |

|

|

101*46*40mm |

|

|

0.005-0.1 mm or at your request |

|

|

CNC,Grinding,EDM,Milling Machine,3DCMM, |

|

|

15-20days after structure approved |

|

|

ISO9001, export standard |

A Auto checking fixture is a simple tool used by industrial production enterprises to control various dimensions of products (e.g. aperture, spatial dimensions, etc.), to improve production efficiency and control quality, and is suitable for mass-produced products, such as automotive parts, to replace professional measuring tools, such as smooth plug gauges, thread plug gauges, and O.D. gages.

Supplying auto checking fixtures as a value-added service can be highly beneficial, especially in industries where precision and quality control are crucial, such as manufacturing and automotive sectors. HT Tool&Die not only can provide stamping dies but also can provide checking fixtures;Here are some points that supplying checking fixtures can add value to our customers:

: HT auto checking fixtures has strict quality control standards to follow in each production processing,we have ISO9001 system that can ensure our checking fixture can meet with customer requirement.

Aluminum Bases that are more than 18" x 18" require a welded aluminum base, with 4 corner pads

Minimum, for stability. The height of the base is to be no more than 6" and no less than 4" in height,

- Adjusting the part keep it well contact nets and lacat it with X/Y1/Z1 and Y2/Z2.

- Close clamp Z1,Z2,Z3.

- Using the P1 pins to check the hole position.

- Visually detect the edge of the material, it is qualified within +/-1.5 lines, and vice versa.

We have in-house production processing,this is easy to control the quality and will get cost saving.

Népszerű tags: , A fülhallgató -tesztelő szerelvények ellenőrzése, A fejhallgató -tesztelő szerelvények ellenőrzése, A hangszórók tesztelésének lámpatestének ellenőrzése

Egy pár

nemKövetkező

Jig Ellenőrző FixtureAkár ez is tetszhet

A szálláslekérdezés elküldése